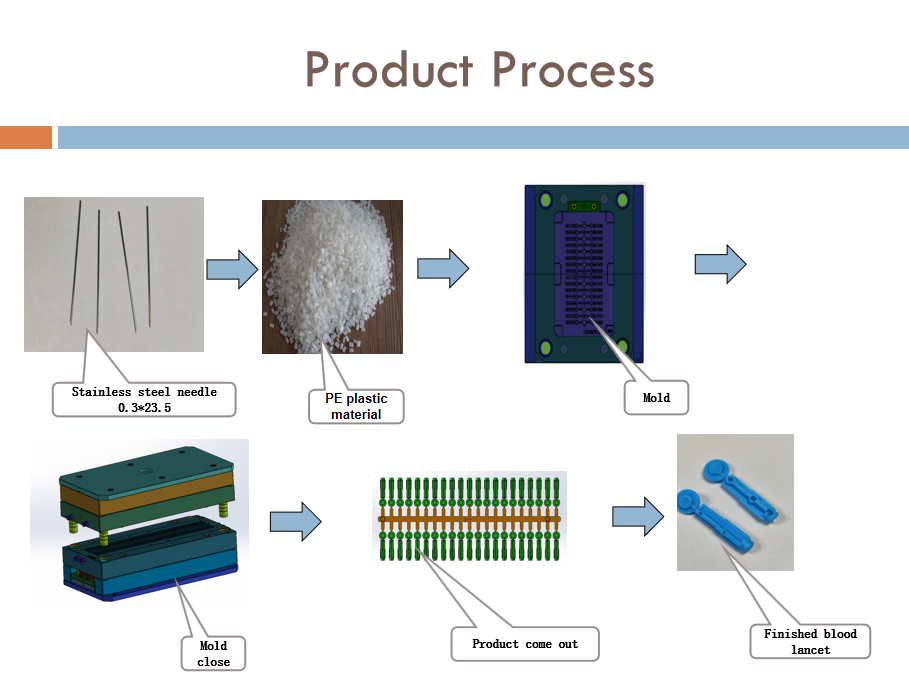

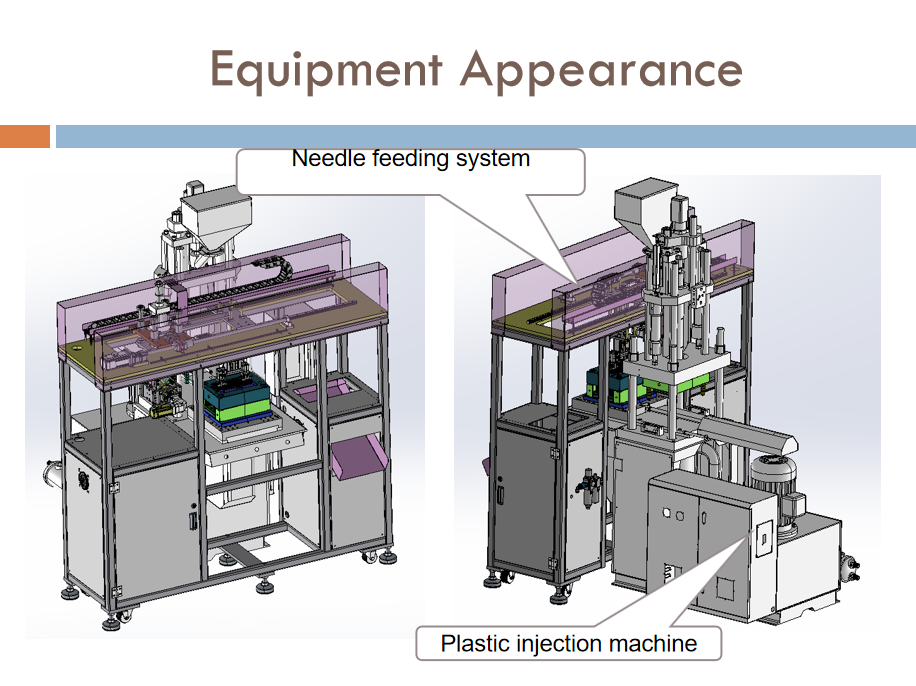

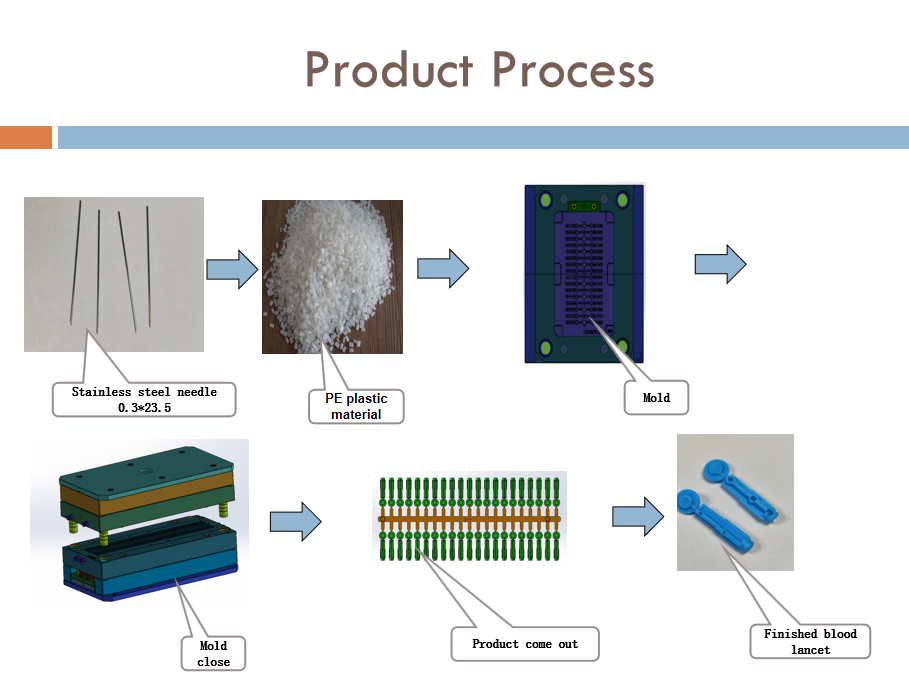

Equipment Description:

1. Intelligent system: Automatic fault alarm accurately indicates the fault location, so as to handle the fault faster and remind the replacement function after the number of wearing parts reaches; 2. Controllable parameters: All key workstations of the equipment can adjust the corresponding parameters on the human-machine interface.

3. Modularization and fast switching methods are more convenient for mold change production and improve production efficiency. The module can be turned on and off according to actual production needs;

4. This equipment can save manpower and automate production.

Equipment performance parameters

I. Basic conditions of the equipment

1. Input power: AC220V /50HZ

2. Working air pressure: 0.55-0.8Mpa (clean and dry air is required)

3. Average power: 7.5KW

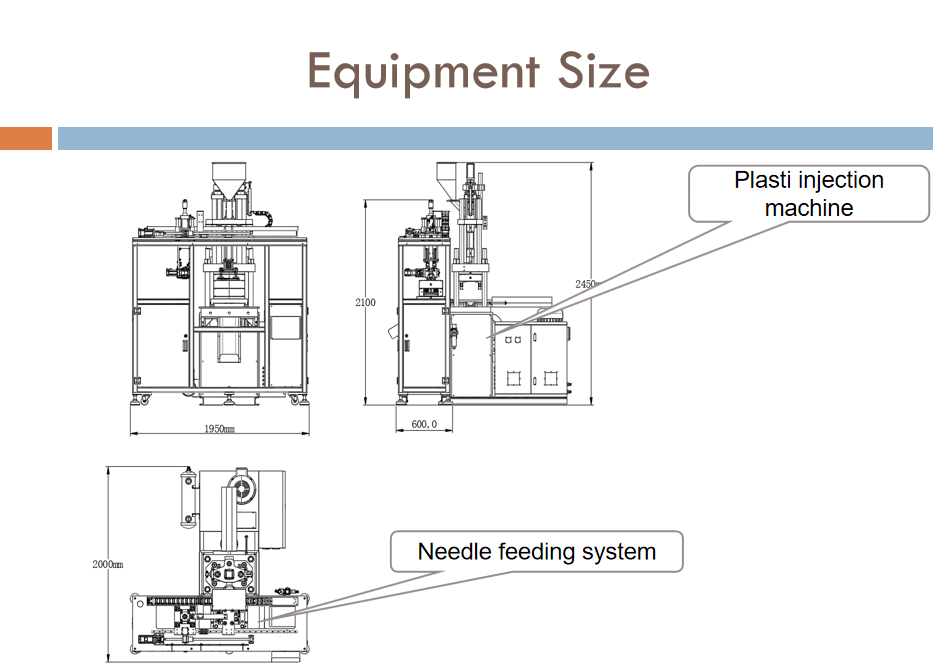

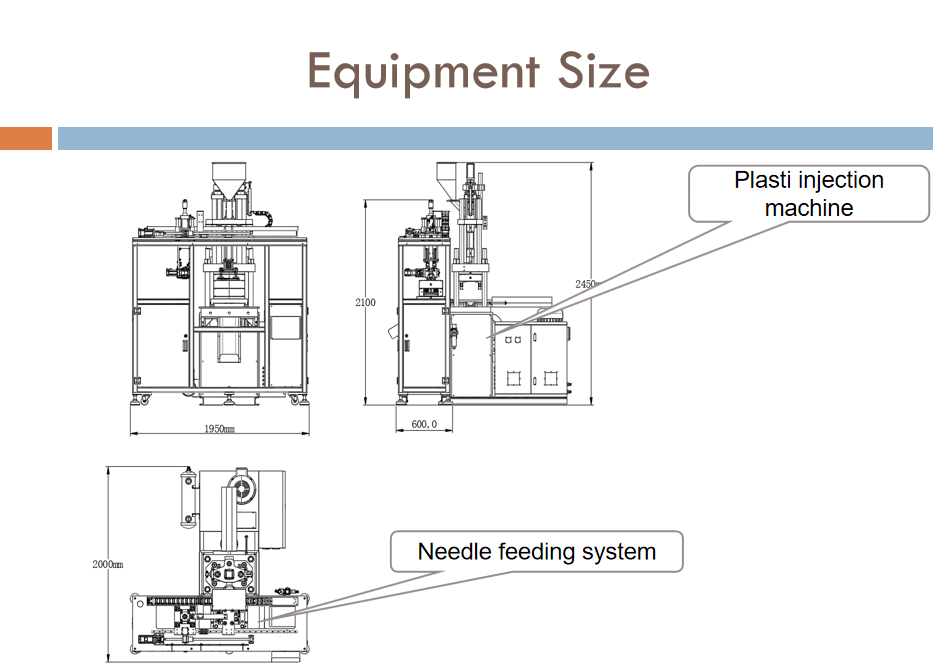

4. Appearance size: 1950*2000*2450

II. Main technical indicators

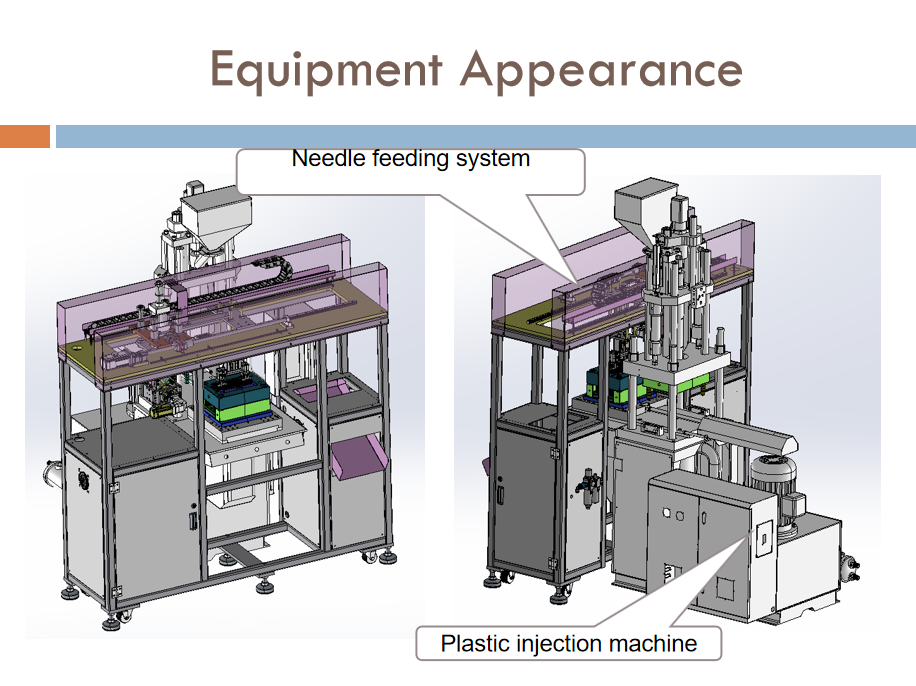

1. This equipment: one output and thirty-two needles.

2. Production efficiency: 22 seconds/mold

III. Materials used in equipment

1. Square steel frame;

2. All steel materials are electroplated for rust prevention (special parts such as blades and sliding parts);

3. Xinjie PLC/man-machine screen, Omron OMR, and Ruiko fiber optic components are used;

4. All cylinders and pneumatic components are of AirTac brand;

5. The motors are Xinjie/Panasonic servo, Reser stepper, and Hong Kong Oriental Motor;

Injection molding machine specifications

Model | Unit | JY-450ST-D |

Screw Diameter | mm | 30 | 32 | 34 |

Theoretical Injection Volume | cm3 | 98.9 | 112.5 | 127 |

Injection Weight(PS) | g(oz) | 93.5(3.3) | 106.3(3.75) | 120(4.23) |

Max. Injection Pressure | Mpa(kgf/cm2) | 170.8(1742) | 150(1531) | 133(1356) |

Injection Rate | cm3/s | 53 | 60.3 | 72 |

Injection Speed | mm/s | 75 |

Injection Stroke | mm | 140 |

Screw Speed Rotation | r.p.m | 0-200 |

Number of Temperature Control | pcs | 3+1 |

Nozzle out from Platens | mm | >45 |

Clamping Force | KN(tf) | 441(45) |

Sliding Table Size | mm | 390*390 |

Distance Between Tie Bere | mm | 410*250 |

Min. Mold Height | mm | 150/250 |

Opening Stroke | mm | 180 |

Max. Opening Mold Distance | mm | 350/450 |

Ejetor Force | KN(tf) | 14.7(1.5) |

Ejetor Stoke | mm | 85 |

Max. Hydraulic Pressure | Mpa(kgf/cm2) | 13.7(140) |

Oil Resservoir Capacity | Liter | 120 |

Pump Motor Power | KW(HP) | 5.5(7.5) |

Barrel Heating Power | KW | 3.4 |

Total Power | KW | 8.9 |

Machine Weight | tf | 1.8 |

Machine Dimension(LxWxH) | m | 1.72*1.1*2.26 |

Why choose us?

● The source factory of injection molding machines with 15 years of R&D, manufacturing and sales experience

● Visual production of complete machine by xiaomi app

● Complete sets certification such as CE,ISO...

● SGS certificated top quality factory

● 7*24 hours online service

● 3 days drawings making and 20 days delivery of customized machine model

● Customized machine controller languages

● Video type machine manual

● Technical documents available on website.

● 200 sets machines monthly production capacity

Our Mission:

Pursue happiness of both physical and spiritual of all employees.

Contribute to the progress of Chinese machinery industry

Our Vision:

Join hands with global best quality suppliers

Serve the world with Chinese equipments

Create a leading brand in Chinese machinery projects

FAQ

Q: Which city are you in? How can visit you? Are you a trading company or factory?

A:Our factory is next to Guangzhou and Shenzhen. We will drive you to our factory by car when you arrive at Dongguan or Changping Railway(Bus) station. We are factory, manufacturing mainly plastic injection molding machines. We offer turnkey solutions with more than 10 years experience.

Q: What is the warranty period for your machine ?

A:12 months warranty for components and technical support .

Q: What is the lead time?

A:For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization and busy season.)

Q: How about the service?

A:We provide life-long online service for solving your problems.